Process technology for industry and commerce

Mature, customized technology

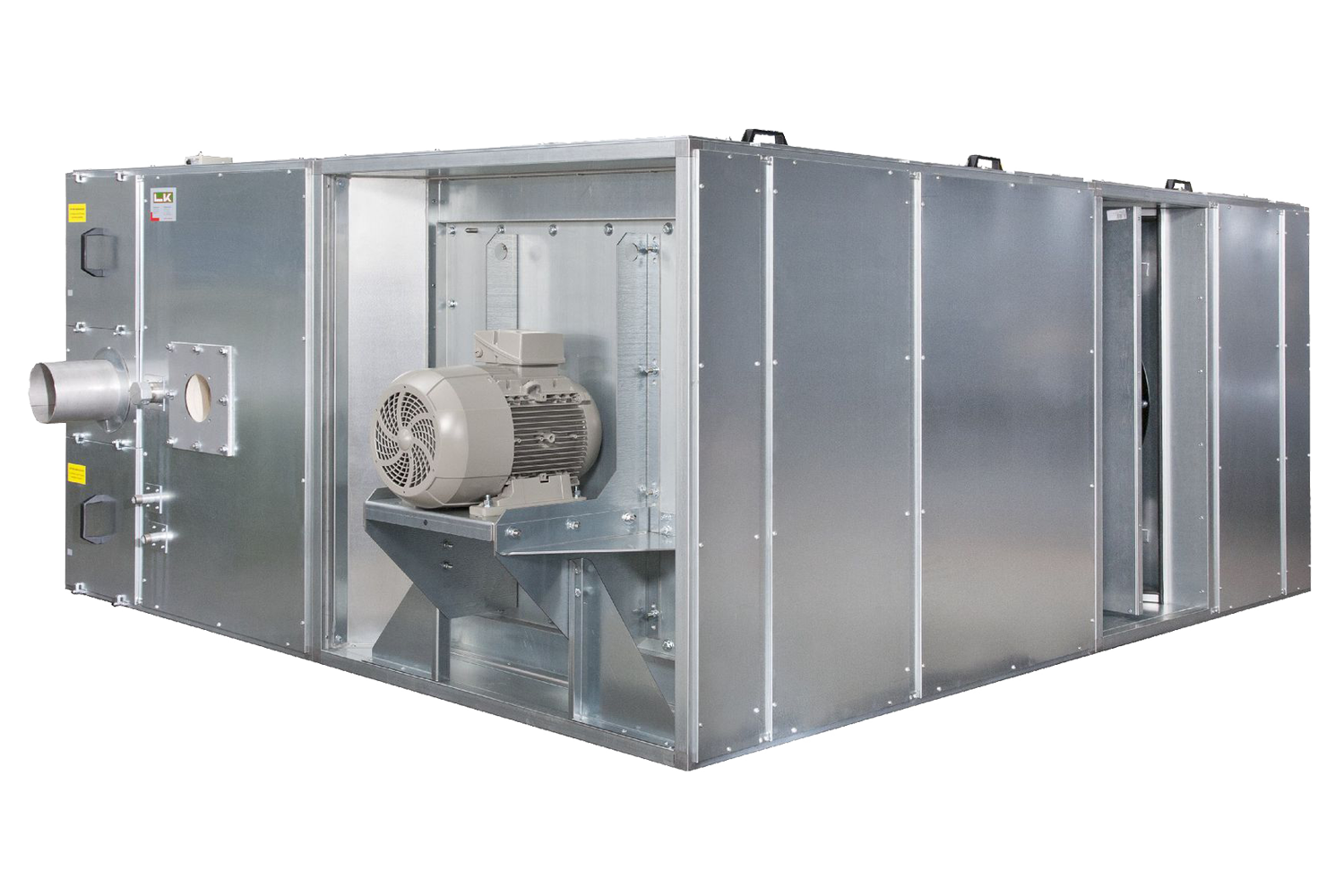

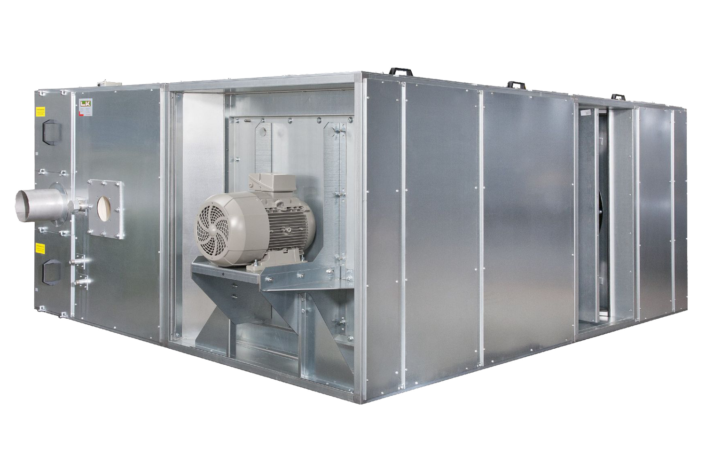

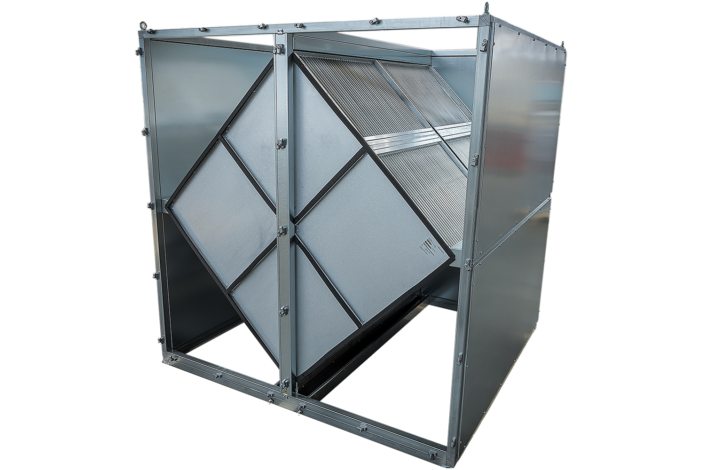

Combustion chambers and process engineering systems for industry and commerce

In the field of process technology, LK Metallwaren offers innovative systems for industry and commerce that bring enormous energy savings. With our LKPT compact coating system and our specific combustion chambers, we reduce the energy requirements of your machines and appliances.