Climate-neutral and efficient heating with local heat

There are more sensible measures for active participation in climate protection by reducing CO2 emissions than tacking on high personal commitment to roads or runways. Climate protection is more successfully pursued with positive-active participation, and a large number of companies already began taking measures to reduce their CO2 emissions several years ago.

This also includes the Middle Franconian company Abel Wellpappe in Form, which, founded in 1997, is currently the market leader in Europe when it comes to processing corrugated board with heights between 3.6 and 7.2 mm into corrugated board pads and contour-precise molded parts. Moreover, the end products are single-material packaging made of corrugated board, which – another sustainability plus point – guarantees sort-free recycling. In 2022, the packaging specialist had decided to convert its previously oil-fired hall heating systems to local heating. The local heat is supplied by a cooperative company from the region, which generates it from the combustion of biogas and wood chips. With the conversion of its heat supply, Abel will be able to produce climate-neutral from now on.

Specially designed to supply production and logistics halls

LK Metallwaren GmbH supplied and installed decentralized warm air heaters with oil burners for the production and storage halls at Abel Wellpappe in Form since 2007.

After the company opted for local heating in August 2022, the oil burners in the existing LK warm air generators in Halls 3 to 8 were removed and a PWW register installed in their place.

The distribution of local heat is now handled by the existing LK warm air generators.

LK Warm air heater RBW with condensing technology

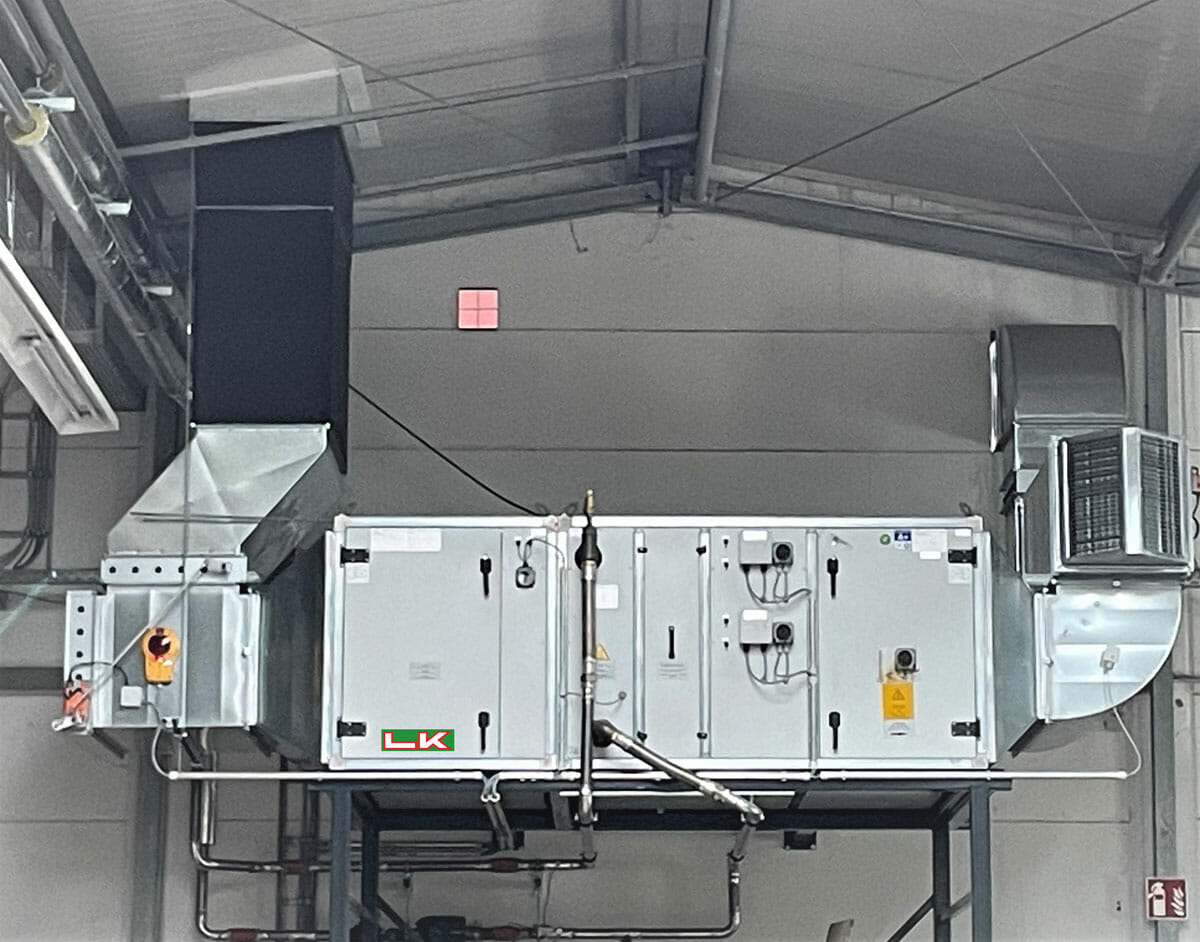

In Halls 1 and 2, the aging oil-fired radiant system was dismantled and replaced with a new LK GCS (Green Climate System) warm air heater. The newly installed system has been specially developed by LK Metallwaren for the heating and ventilation of production and logistics halls. With it, the two hall areas can henceforth be heated independently of each other via a two-room control system.

The plant is equipped with a mixed air device, through which the hall is supplied with outside air. The operator can independently determine the proportion of outside and recirculated air to be introduced into the hall on a scale of 0 to 100 percent. During the heating period, for example during break times, intermittent ventilation can be carried out via an interval control system, thus saving considerable costs compared to continuous ventilation.

LK Warm air heater GCS (Green Climate System)

However, the LK Warm Air Generator GCS is not only capable of converting cold air into warm air: It also goes the other way. In this way, it ensures a pleasant, precisely controllable hall climate via night cooling even in the warm season. For the summer months, summer/night cooling is stored in the control system. By means of this option, the hall climate can be optimized over the cooler night temperatures. The best possible time for this is usually between 11 pm and 7 am. In order to prevent a possible cooling of the hall, a temperature limit can be specified.

Use with other regenerative heating sources

The LK warm air generator GCS can also be used for other regenerative energy sources. For example, for air heating in the hall can be installed a special heating and cooling coil, which is connected to a cascade of several connected heat pumps.

Heat pumps filled with R32 refrigerant or R290 natural refrigerant are used for this purpose. The integrated filter additionally ensures that the intake air is filtered throughout the entire air exchange and thus cleaned of dirt and dust particles.

Reimbursement of costs by BAFA

And there is another significant plus point: those who opt for the GCS can significantly reduce their acquisition costs. The German Federal Office of Economics and Export Control (BAFA), for example, offers support for new installations in the form of subsidies of up to 40 percent. This is another way to save resources!

For the founder and managing director of Abel Wellpappe in Form Roland Abel, the decision to switch from heating oil to local heating has more than paid off. Because: “We now not only have a climate-neutral heat supply, but have also made ourselves independent of the use of finite resources.”