Hall heating with a heat pump – when is it worthwhile?

Heating halls is a challenge that companies have to master. Energy efficiency, sustainability and operating costs are three decisive factors. In this guide, you…

The installation work on the two LK ventilation systems is progressing!

The installation work on the two LK ventilation systems LKPT 24x24 is progressing rapidly! We are currently installing two large LKPT 24x24 process ventilation systems…

A look back at IFAT 2024

The IFAT 2024the world's leading trade fair for water, sewage, waste and raw materials management, took place in Munich from May 13 to 17. LK-Metall is proud to…

What is a solar air collector?

A solar air collector uses air instead of water as a heat transfer medium and can reduce heating costs by up to 30 percent!

In this article, we would like to…

Expansion: New service vehicles in the hall heating division

The expansion of the service vehicles in the hall heating division is continuing!

The switch to the Mercedes Sprinter and Vito provides our assembly and service…

Successful conclusion at the IFH Intherm trade fair 2024

The IFH Intherm trade fair in Nuremberg ended extremely successfully on April 26, 2024. The entire heating, sanitary and air conditioning industry was represented.…

Plant engineering in transition: sustainability in focus

In a world characterized by global upheaval and geopolitical changes, the industry is also undergoing a transformation. Harald Wimmer, Sales Manager at LK Metallwaren…

Heat halls CO2-neutrally!

On 23.04.2024 the

ifh INTHERM

in Nuremberg will open its doors. The trade fair for sanitary, home and building technology will showcase the latest trends in…

Successful model “Made by LK”: overseas with flame tube and heat shield

Wherever surfaces need to dry as quickly and evenly as possible, particularly powerful and highly reliable ventilation units are required: this also applies to systems…

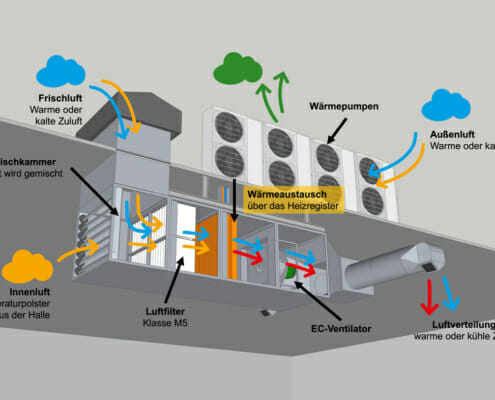

Climate-neutral heating and ventilation of halls

LogiMAT in March 2024

From 19.03. LogiMAT - the international trade fair for intralogistics and process management will take place as usual from March 1 to 21, 2024.…

Climate-neutral and efficient heating with local heat

There are more sensible measures for active participation in climate protection by reducing CO2 emissions than tacking on high personal commitment to roads or runways.…

Optimal climate throughout the year

Resource-saving - cost-saving - climate-friendly: With the LK Warm Air Generator GCS, LK Metallwaren has developed a new generation of hall heaters. It guarantees…

Efficient heating – intelligent ventilation

This year, the Stuttgart LogiMAT will again be held with the participation of the plant manufacturer LK Metallwaren. From April 25-27, 2023, this will bring its…

The time is ripe for hybrid hall heating systems!

The Climate Protection Act has been in force since August 2021.

The German government has tightened climate protection targets and enshrined the goal of greenhouse…

Dust-free feel-good climate without drafts on 4,500 sqm

The German fashion retailer mister*lady relies on energy-efficient heating without dust and drafts. LK Metall installed an innovative heating and ventilation system…

Three different temperature ranges for sensitive goods

Euphoniums, cajons and agogos - all these wonderful musical instruments can be found in Treppendorf in the Steigerwald in the 7,700 square meter logistics halls…

Regulate 32,000 sqm to constant 18 °C hall temperature

The RBW decentralized warm air generators from LK Metall are an efficient and climate-friendly heating solution for large production halls.

In order to heat the…