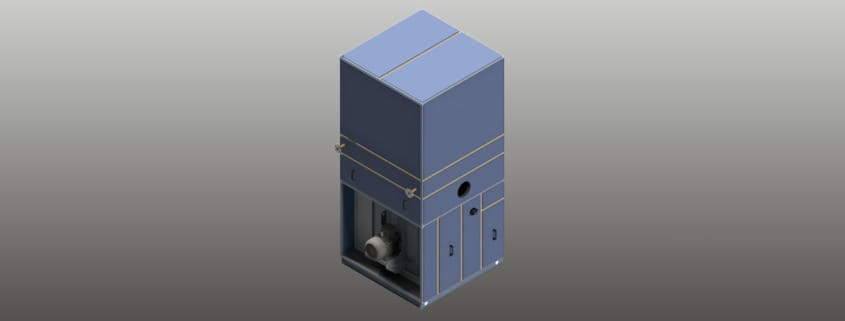

Successful model “Made by LK”: overseas with flame tube and heat shield

Wherever surfaces need to dry as quickly and evenly as possible, particularly powerful and highly reliable ventilation units are required: this also applies to systems used in the furniture construction and furniture processing sector.

In May 2023, LK Metallwaren produced two ventilation systems at its main site in Schwabach.

ventilation systems to a Westphalian company that specializes in plant engineering for furniture production. The components that LK Metallwaren supplied to the customer were intended for use in wood processing, specifically for drying furniture components after surface treatment. The process air used for this process air is heated in a temperature range between 60 and 80 degrees Celsius.

In this way, the applied coatings can dry much more quickly, packaging and shipping of the parts can be carried out faster and delivery times can be shortened. To achieve this with maximum efficiency and effectiveness, LK Metallwaren has equipped the newly designed ventilation systems with flame tubes and heat shields. Both systems were integrated by the customer into their systems and then shipped to their own customers overseas, in this case to Canada and the USA.

Two further deliveries in September and November 2023 as well as two current orders for next spring from the same customer not only show that the systems have been “well received”, but have also been successfully put into operation by the end customers The two current orders finalized with the customer were also delivered to companies overseas: one to a furniture manufacturer and the other to an instrument maker from the United States. Of the ventilation units ordered for delivery in spring 2024, one will be sent from the customer to Canada and a second to a furniture manufacturer in Baden-Württemberg.

The delivered or ordered systems differ fundamentally only in the means by which the process air is heated. Gas is generally preferred in the plants that were delivered overseas. In the domestically supplied system, a pumped hot water coil is used for the volume flow of 20,000 cubic meters of air per hour to be generated.

Further orders for this current successful model “Made by LK” are expected to follow soon. Customer-specific modifications are possible here, in addition to the type of heat generation, especially in the dimensioning and performance of the units.